Solder Wire, Solder Bar, Solder Paste Manufacturer

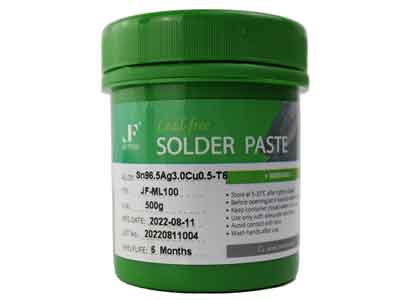

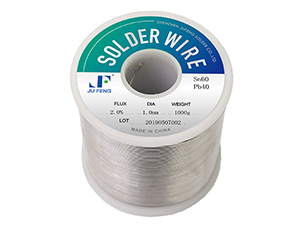

The demand for lead-free solder has increased dramatically since the 2006 restriction came into effect for intentionally leaded consumer electronics. As a dedicated OEM manufacturer, JUFENG can provide lead-free solder wires with a diameter of 0.1mm or greater. Our massive inventory also includes a premium selection of solder ball, flux, paste, and powder.

Shenzhen Jufeng Solder Co., Ltd.

TEL: +86-755-89501348

+86-755-89501587

Mobile: +86-13622394561

FAX: +86-755-89501292

Contact Person: Pauline Lee

Email: info@jufengxi.com